Circular Saw Blade Size Guide & Accessories: How to Choose the Right Blade for Every Cutting Task Leave a comment

In professional woodworking, construction, and metal fabrication, the circular saw blade remains one of the most critical components for achieving precision, efficiency, and material consistency. Each blade type has its own performance characteristics defined by diameter, tooth geometry, and core material. Selecting the proper blade requires understanding not only its size but also how cutting parameters, blade design, and accessories interact to influence overall results. This guide provides a professional overview of blade sizing, metal cutting optimization, and system maintenance to help engineers, fabricators, and tradespeople achieve better results.

1. Understanding Circular Saw Blade Size and Cutting Parameters

Choosing the correct blade diameter is fundamental to both accuracy and safety. Circular saw blades range from 110 mm (4½”) for compact tools to 305 mm (12″) for industrial saws. Blade size determines cutting depth, torque distribution, and energy consumption.

| Blade Diameter | Max Cutting Depth | Application |

|---|---|---|

| 110–165 mm | 30–50 mm | Portable tools, trim work |

| 184–190 mm | 60–65 mm | Framing and construction |

| 250–305 mm | 75–100 mm | Heavy-duty or precision cutting |

Key considerations:

- RPM compatibility: Each blade has a maximum safe speed. Over-spinning can lead to vibration, imbalance, or even failure.

- Kerf width: A thin-kerf blade offers smoother cuts and less resistance but may flex under high feed pressure.

- Tooth geometry: Alternate Top Bevel (ATB) provides clean wood cuts, while Triple Chip Grind (TCG) handles aluminum and steel.

- Arbor size: Always match the arbor to the blade hub for consistent rotational balance.

A properly sized blade improves cutting precision and ensures energy-efficient operation while minimizing tool wear.

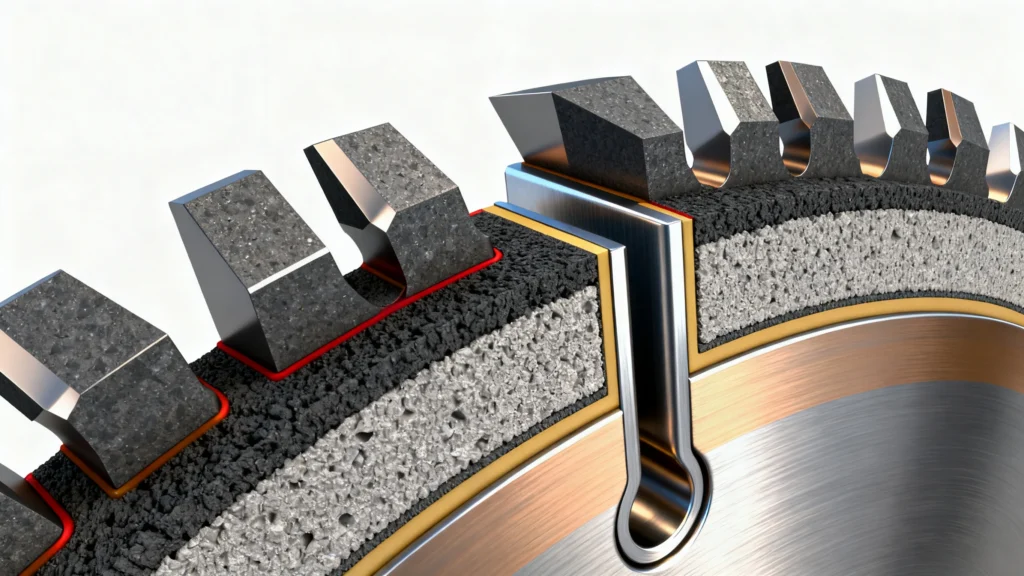

2. Metal Cutting Circular Saw Blades: Materials and Design

A metal cutting circular saw blade must withstand high temperatures and continuous stress. Compared to wood-cutting blades, metal blades feature different tooth geometries and materials optimized for strength, hardness, and wear resistance.

Core features include:

- Tungsten carbide or cermet-tipped teeth for enhanced durability and edge retention.

- Laser-cut expansion slots to dissipate heat and maintain alignment.

- Hardened steel or alloy cores that resist warping under pressure.

- Protective coatings such as TiN, TiAlN, or CrN to reduce oxidation and surface friction.

- Optimized tooth count: Fewer teeth (around 36–48) for faster cutting through thick stock, more teeth (up to 100) for fine finishing.

Professional fabricators often refer to international standards like the ISO 3002-1:2019 Tool Geometry Standard, which outlines precise technical parameters for cutting tool angles and tolerances.

Metal blades are suitable for mild steel, stainless steel, non-ferrous alloys, and even reinforced plastics. However, each requires different cutting speeds and lubrication methods to avoid overheating or premature dulling.

3. Material Compatibility and Cutting Efficiency

Different materials react differently to blade geometry and speed.

For example, aluminum requires high RPMs and fewer teeth to avoid chip welding, while stainless steel benefits from slower feed rates and continuous coolant flow. When selecting a circular saw blade for metalwork, users should consider:

- Thermal load tolerance: Excess heat leads to tooth softening and burr formation.

- Feed pressure: Maintain consistent feed to avoid vibration or blade wandering.

- Material hardness: Adjust speed according to Brinell hardness or tensile strength.

- Chip evacuation: Use proper tooth spacing to prevent clogging in non-ferrous materials.

Industry resources like Machinery’s Handbook Online provide detailed reference tables for cutting speed, chip load, and surface finish when using circular saws for different metals.

4. Circular Saw Accessories and System Integration

Circular saw accessories are essential for ensuring precision, safety, and tool longevity. They help operators maintain better control while improving overall cutting accuracy.

Key accessories include:

- Guide rails and parallel fences for maintaining accurate linear cuts.

- Dust extraction systems to improve visibility and reduce airborne particles.

- Anti-vibration mounts that stabilize the saw under heavy load.

- Lubrication systems to dissipate heat and prevent galling.

- Protective guards and spark deflectors to enhance workplace safety.

When paired with high-quality accessories, even mid-range circular saws can deliver industrial-grade cutting precision. Consistent system calibration—checking for blade alignment, fence straightness, and guard tension—is equally important to maintain accuracy across repetitive operations.

5. Maintenance and Performance Optimization

Even the best circular saw blade requires ongoing maintenance to preserve performance and ensure operator safety.

Regular care minimizes the risk of cracking, vibration, or thermal distortion.

Maintenance checklist:

- Cleaning: Remove resin or metal buildup with a non-corrosive solvent after every use.

- Inspection: Check tooth symmetry and tensioning rings regularly.

- Sharpening: Use diamond wheels for carbide or cermet-tipped blades.

- Lubrication: Apply cutting fluid when processing thick metals.

- Storage: Keep blades vertical with protective spacers to prevent warping.

Proper maintenance practices extend service life by up to 40%, reduce replacement frequency, and ensure smoother, quieter operation.

For production environments, it’s recommended to document blade life cycles and sharpening intervals to maintain consistent output quality.

6. Operational Guidelines and Safety Considerations

Cutting performance depends on a balance between blade design, feed rate, and rotational speed. Overfeeding causes tooth wear, while underfeeding can lead to overheating or edge burn.

Professional users should follow these core operational guidelines:

- Match feed pressure and RPM to blade diameter.

- Maintain consistent cutting angles to prevent friction-induced heat.

- Avoid using one blade for multiple material types.

- Replace blades showing dullness, burr formation, or burn marks.

- Ensure all mounting components are properly torqued and vibration-free.

Safety must remain a top priority. Operators should always wear protective eyewear, gloves, and hearing protection, especially when cutting metal or high-density composites.

7. Summary & About CISIVIS

Selecting the correct circular saw blade involves balancing multiple parameters—size, tooth geometry, material composition, and operational speed. Understanding how each factor affects cutting efficiency can significantly improve both productivity and finish quality. Whether working in metal fabrication, woodworking, or composite machining, precision depends on a well-matched system of blades, accessories, and maintenance routines.

CISIVIS is a leading manufacturer and supplier of high-quality power tools and circular saw blades, specializing in solutions for woodworking, metal fabrication, and industrial applications. With a focus on precision engineering, durability, and innovation, CISIVIS products are designed to meet the demands of professional craftsmen and industrial workshops. By combining advanced manufacturing techniques with rigorous quality control, CISIVIS ensures every tool delivers optimal performance, reliability, and long service life—providing professionals with the cutting solutions they need for maximum efficiency.