Impact Wrench vs Driver: How to Choose the Right Tool Leave a comment

impact wrench vs driver: What Each Tool Is and How It Works

Impact Wrench

An impact wrench is a power tool that delivers very high rotational torque in short bursts. It’s often used to loosen or tighten heavy nuts and bolts that are hard to move by hand. The tool usually uses a “hammer-and-anvil” or “hammer clutch” mechanism: the motor spins a hammer, then the hammer strikes an anvil, which delivers torque to the output shaft. Because of that impact mechanism, it can break loose stubborn bolts or tighten bolts tightly without the user needing to push too hard.

Impact wrenches come in many forms: pneumatic (air-powered), corded electric, and cordless (battery powered).

Impact Driver

An impact driver is a tool more specialized for driving screws, bolts, and fasteners rather than those big nuts. It also uses a hammer-mechanism, but on a smaller scale, to add torque to the turning motion. When resistance is met (for example, when a screw is tough to turn), the driver’s hammer system kicks in to help push through. Because it is lighter and more compact, it is ideal for general use, DIY, woodworking, cabinet work, and tasks where you need to drive many screws quickly.

So in short: an impact wrench is for heavy torque tasks, an impact driver is for fastening screws and lighter bolt work.

Market Trends: How “Impact Wrench vs Driver” Is Evolving

Let’s look at how the markets for impact wrenches and impact drivers are growing, and compare their trends. I use reports and journals to support this.

Impact Wrench Market Trend

- The global impact wrenches market was valued at about USD 2.3 billion in 2022, and it is forecasted to grow to USD 3.8 billion by 2031, with a compound annual growth rate (CAGR) of 5.4 %.

- The cordless (battery) impact wrench segment is gaining traction, with a reported CAGR of around 4.6 % from 2021 to 2031.

- There is a shift toward higher-voltage rechargeable impact wrenches, because people demand more powerful tools for tougher jobs.

- The Asia-Pacific region is projected to be a fast-growth area, driven by infrastructure development, while North America holds a strong, stable market share in mature segments.

Impact Driver Market Trend

- The global impact driver market is also growing steadily. One report values it at USD 3.5 billion in 2024, and projects growth to USD 5.8 billion by 2033, with a CAGR of 7.3 %.

- The faster growth rate of drivers relative to wrenches suggests rising demand in general construction, DIY, renovation, and light assembly sectors, where impact drivers are well suited.

- In search trends, “impact driver” as a keyword often shows higher interest than “cordless impact wrench,” reflecting widespread usage and consumer awareness.

Trend Comparison: Impact Wrench vs Driver

- Impact drivers are growing faster (≈ 7.3 % CAGR) than wrenches (≈ 5–5.4 % CAGR), which makes sense because drivers cover a broader base of lighter tasks.

- Wrenches are moving toward more specialized, high-power, rugged tools, especially in industrial, automotive, and construction fields.

- Drivers benefit from the expansion of DIY culture, home renovation, and general-purpose building work.

- In many tool kits, the two are complementary rather than competing: professionals often carry both. Indeed, many tool manufacturers now bundle or promote both to users.

- From keyword trends, “impact wrench vs driver” is a useful SEO phrase because many people search to compare these two tools.

Thus, both markets are healthy, but in different niches: heavy torque vs broad fastening.

Use Cases: When to Use Impact Wrench, When to Use Impact Driver

In which scenarios you should pick a wrench vs driver. I’ll explain by price, function, practical scenario, and pros/cons.

Scenario 1: Automobile / Mechanical Work

- Impact Wrench is ideal for loosening and tightening lug nuts, large bolts on engines or suspension parts, and heavy fasteners.

- Impact Driver may struggle or fail: it doesn’t provide enough torque for many automotive bolts, or will drain the battery fast.

- For example, a tire shop worker uses a ½″ torque wrench or impact wrench to remove wheel lug nuts quickly.

Price & Function: High-torque impact wrenches are more expensive (especially brushless, high-voltage, or pneumatic models), but necessary for those tough bolts. Lower-end drivers are cheaper but cannot match the torque.

Scenario 2: Home Improvement / Woodworking / Cabinetry

- Impact Driver shines: driving long screws, deck screws, sheet-rock screws, furniture assembly, framing, etc. It’s lighter, compact, and efficient.

- Impact Wrench would be overkill and awkward: too heavy, too much torque, risk stripping screws or damaging wood.

Example: Installing deck boards, cabinets, or drywall you will prefer impact drivers.

Scenario 3: Light Machinery & Equipment

- Small bolts on machines, mounting brackets, or light structural bolts: sometimes an impact driver (with the right bits) is enough.

- But if bolts are large or highly torqued, or rusted/seized, switch to impact wrench.

Scenario 4: Construction / Heavy Building

- Impact wrenches are useful for structural bolting, scaffolding, steel connections, large fasteners on beams.

- Impact drivers assist in secondary tasks: connecting small brackets, fasteners to wood, running screws to secure lights, etc.

Detailed Comparison Table (for decision)

| Factor | Use Wrench | Use Driver |

|---|---|---|

| Torque needed | High torque required (e.g. 150+ ft-lb or more) | Moderate torque (e.g. driving screws) |

| Fastener type | Nuts, bolts, lug nuts, heavy hardware | Screws, lag bolts, self-tapping fasteners |

| Weight & size concern | Heavy tools acceptable | Prefer lighter, compact tool |

| Cost | More expensive, especially high-end models | More affordable for general use |

| Precision torque control | Some models support torque settings or clutch control | Less precise torque control; switch to torque driver if needed |

| Risk of damage | Risk of overtightening if not careful | Risk of stripping if torque too low or bit not suitable |

| Battery load | Large battery often required | Smaller battery or more efficient use |

| Speed and convenience | Good for fast removal and installation of large bolts | Good for repetitive screw driving |

Which to Choose in Specific Situations

- Changing car tires: always use an impact wrench (or at least a ½″ driver with high torque).

- Putting together furniture or cabinets: impact driver is perfect.

- Outdoor deck building: driver for screws; wrench if any large structural bolts used.

- Repairing heavy machines, scaffolding, structural work: impact wrench.

- DIY in the workshop / home: an impact driver is usually enough; keep a small wrench or torque wrench for special tasks.

One insight from users:

“An impact wrench can loosen or drive some screws but it’ll strip or snap many. Likewise an impact driver will be underpowered for many properly torqued bolts.”

So they overlap a little, but trying to replace one with the other has risks.

Common Problems & Solutions

Here are frequent issues users face with both impact wrenches and drivers, and how to solve them. I’ll also attach a simple diagram / explanations to help.

Problem A: The tool doesn’t generate enough torque / fails to drive a bolt or screw

- Cause: battery low, bit slipping, wrong size bit, tool in wrong mode, fastener too tight or seized.

- Solution:

1. Charge battery fully; use high-capacity battery.

2. Use correct size socket or bit, ensure it’s in good condition.

3. Check mode or setting (some tools have multiple torque or speed modes).

4. Use penetrating oil or apply heat if bolt is seized, then try again with impact wrench for stubborn bolts.

5. If battery is good but power is low, test tool internals (brushes, motor, gearbox).

Principle: The tool needs sufficient input power and an effective transmission through the impact/hammer mechanism to the fastener. If any link in that chain is weak, torque drops.

Problem B: Stripped screw heads, rounded bolt corners

- Cause: incorrect bit or socket, bit slipping, too much torque suddenly, poor engagement.

- Solution:

1. Use high-quality impact-rated bits or sockets.

2. Ensure bit fits tightly, no play.

3. Start at lower torque mode or lower speed before full power.

4. Gradually increase torque rather than sudden full blast.

5. If head is already damaged, use extraction bits or bolt extractors.

Principle: The hammer hits in pulses; if the fastener / bit interface is weak, pulses will shear or deform the head rather than drive it.

Problem C: Too much vibration, user fatigue, or tool damage

- Cause: imbalance, internal parts worn, user holding incorrectly.

- Solution:

1. Maintain the tool: clean, lubricate, tighten internal parts.

2. Use anti-vibration gloves, proper stance, maintain grip.

3. Use a lower speed or mode if available.

4. Replace worn parts (hammer, anvil, bearings).

Problem D: Torque control / over-tightening

- Cause: impact wrench is not precise (often pulsed), over-driving.

- Solution:

1. Use a torque wrench for final tightening when precise torque is required.

2. Use impact tools with adjustable clutch or torque settings.

3. For critical joints, use the wrench to snug, then torque with a calibrated tool.

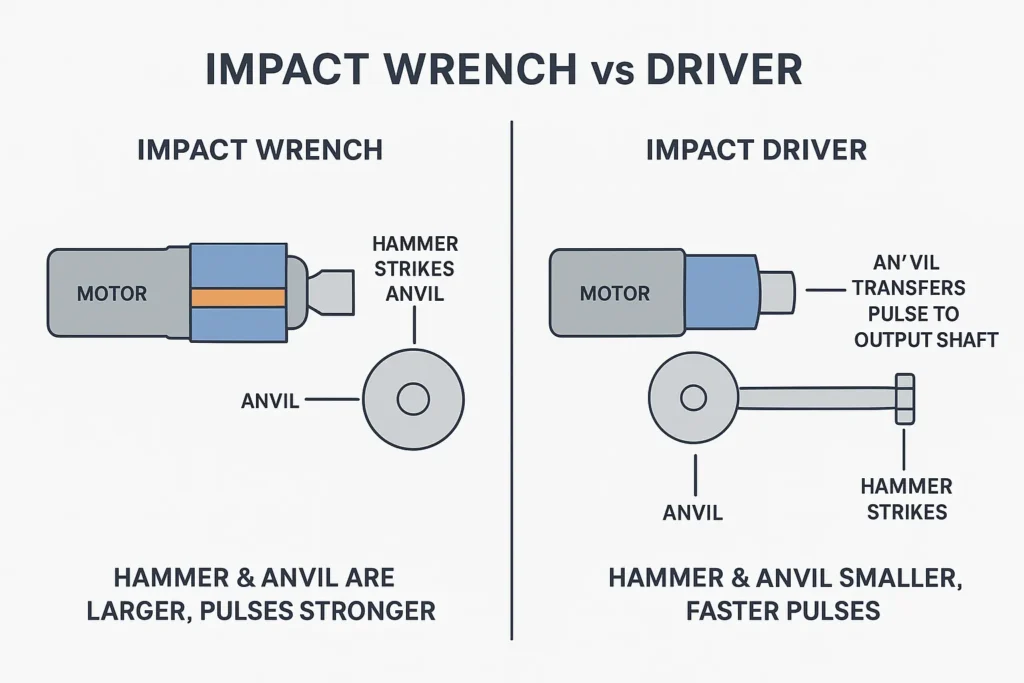

Diagram / Simple Illustration

Below is a conceptual simplified diagram to show how hammer-and-anvil works in both devices:

Motor → Hammer mechanism → Hammer strikes Anvil → Anvil transfers pulse to output shaft → Fastener

In impact wrench: Hammer & anvil are larger, pulses stronger

In impact driver: Hammer & anvil smaller, faster pulses

Also common is the “pin clutch” or “double hammer” mechanism in wrenches, where multiple hammers strike the anvil in alternation, giving more power.

Conclusion

In summary, impact wrench vs driver is not about which is better overall, but which is better for your task. Use an impact wrench when you need high torque for bolts, nuts, automotive or structural work. Use an impact driver when you need fast, efficient driving of screws and lighter fasteners. The markets for both are growing—drivers faster in general usage, wrenches steadily in industrial / automotive niches.

When building your tool kit, having both (or at least one plus a reliable torque wrench) is often the best choice.

Finally, if you’re exploring quality tools, check out cisivis’s line of impact wrenches and drivers—they are designed for performance, reliability, and user-friendly operation.