How does a drill chuck work? 2

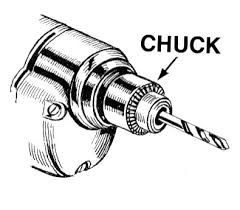

One component that you may take for granted when using a power drill is the drill chuck. The chuck, at the top of the drill spindle, is vital. It ensures the tool operates with efficiency and safety. The chuck is the device that secures the drill bit in place. Without it, your drill bit can slip or wobble. It might even fall off, ruining your accuracy. Knowing what a drill chuck is and how it works will help you control your drill. This will lead to efficient, high-quality work. When drilling holes in wood, metal, or other materials, know the drill chuck. It will help you choose the right bit, secure it, and get the best results.

In this blog, we will dive into the mechanics and types of drill chucks and learn how they work. Let’s explore drill chucks together!

Types of Drill Chucks

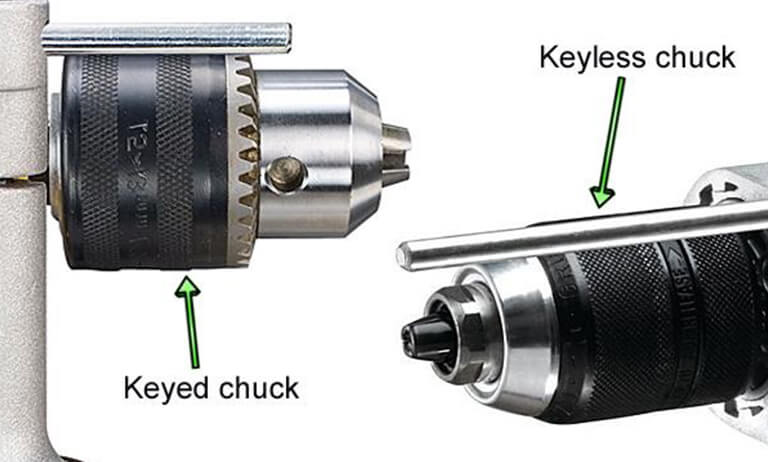

When choosing a drill chuck, you will encounter three main types: keyed, keyless, and hybrid. Each offers its own set of features and benefits tailored to specific tasks.

Keyed Drill Chucks

Keyed chucks are the traditional choice, known for their solid grip and reliability. With these chucks, you use a chuck key to tighten or loosen the jaws, ensuring a firm hold on the drill bit. This is crucial when using larger, more powerful drill bits. It also applies to materials that require higher torque. Keyed chucks are most common in precision and power industries. These include construction, manufacturing, and metalworking. For heavy-duty materials like steel or thick wood, use a keyed chuck. It will keep your bit in place, preventing slippage and ensuring accuracy.

Keyless Drill Chucks

Manufacturers design keyless chucks for convenience and speed. You don’t need a chuck key to tighten or loosen the jaws—just twist the chuck by hand. Keyless chucks are ideal for tasks needing frequent bit changes. They suit lighter work, like home improvement, carpentry, and assembly.

A keyless chuck is best for:

building furniture

installing cabinets

drilling small pilot holes

It lets you work quickly and efficiently.

Hybrid Drill Chucks

Then, there’s the hybrid chuck, which combines the best of both worlds. It provides the quick, easy operation of a keyless chuck, but with the added strength of a keyed chuck’s design. Hybrid chucks are perfect for versatile pros. They tackle both heavy-duty and lighter tasks. They allow for fast bit changes without losing grip strength. They’re great for switching between different tasks. For example, general contractors move between heavy-duty and lighter tasks all day.

Keyed chucks deliver exceptional precision in power drilling and achieve accuracy within ±0.005 inch tolerance. The combination of precision and superior torque control makes it a vital component in professional and DIY projects.

Modern drills come with keyless designs, but traditional keyed chucks remain unmatched for heavy-duty work that requires zero bit slippage. The drill chuck’s connection point between the power tool and its bits maintains a strong grip during demanding tasks.

This piece explains the working mechanism of keyed chucks and their comparison with keyless options. You’ll find details about common sizes ranging from 1/4-inch to 1/2-inch. The mechanical principles and selection criteria will help you pick the right type that matches your drilling requirements.

Understanding Drill Chuck Fundamentals

A drill chuck connects your power tool to its bits. This mechanical device holds the drill bit firmly and lets it spin with the drill’s motor. Even the most powerful drill won’t work right without a good chuck that transfers energy to the bit properly.

What is a drill chuck?

A drill chuck holds your drilling tool and connects it to the machine. Most designs have three clamping jaws set up like points on a star. These jaws work together and apply even pressure from three sides. Your drill bit stays perfectly centered this way [1]. This three-point clamping system is a vital part of keeping everything accurate while you work.

Power drills usually come with keyed or keyless chucks. Keyed chucks need a special toothed key that fits into the chuck’s teeth. This key turns an internal screw that moves threaded jaws along a tapered surface [2]. You can really tighten these chucks down hard, which makes them great for heavy-duty work [3]. Keyless chucks are easier to use by hand but won’t grip quite as tight.

Chuck size is something else you need to think about. They usually range from 1/4-inch to 1/2-inch. This size tells you the biggest drill bit shank that will fit. Here are the standard sizes:

1/4-inch chucks: Smaller, lighter, and typically found on less powerful drills

3/8-inch chucks: The middle ground, offering versatility for home use

1/2-inch chucks: Larger, professional-grade chucks for heavier applications

The chuck’s mounting system matters too. Hand-held drills use threaded connections with set screws that keep the chuck from spinning off in reverse [4]. Stationary machines often use tapered arbor mounts that give better power transfer and precision.

How chuck design affects drilling performance

Your drill’s performance depends a lot on its chuck’s design and quality. Precision matters most – good chucks barely wobble or “runout”. Some pro models achieve runout as low as 0.0006 inches [3]. This precision gives you more accurate holes and helps your drill bits last longer by reducing side stress.

The clamping jaws’ material quality really matters. These parts open and close all the time, so they wear down. Cheap metals wear out fast, but high-quality ones keep gripping well for years [4]. Better chuck designs use ball thrust bearings that cut down friction and give you more drilling power [2].

The chuck’s grip strength makes a big difference in how well it works. Pro-grade chucks can grip with over 75 ft-lbs of force, so your bit won’t slip during tough jobs [3]. Some newer models even tighten themselves more as drilling gets harder.

You need even jaw pressure for precise work. The drill bit stays centered and makes consistent holes only when all three jaws push with exactly the same force [4]. That’s why quality chucks are worth it when you need exact measurements.

Chuck design changes how easy the drill is to use too. Keyed chucks grip better but need both hands and you have to keep track of the key. Keyless chucks are faster to use and better when you switch bits often.

Keyed Chuck vs. Keyless Chuck: A Detailed Comparison

At the time you’re picking a power drill, you’ll face a vital decision between a keyed chuck and a keyless chuck. These two different mechanisms impact your work efficiency and drilling precision.

Torque and gripping power differences

Keyed chucks give you a stronger grip on drill bits than their keyless counterparts. You’ll notice this superior clamping power while drilling through rigid materials or using larger bits. The chuck key lets you manually tighten the jaws and apply more torque to secure the bit firmly.

The key’s toothed design creates a mechanical advantage. Users can achieve tighter clamping than they could by hand alone. This stops bit slippage during high-resistance operations, especially with hole saws or mortar mixing [5]. A keyed chuck delivers better results for drilling holes larger than 1/2 inch in steel or other tough materials.

Standard keyless chucks depend on hand strength to secure bits. They might not grip well enough for demanding jobs. But premium self-tightening keyless models are a great match. These high-end options automatically increase their grip as drilling resistance goes up [3]. They use advanced mechanisms that turn rotational resistance into extra clamping force.

Precision and runout comparison

Different chuck designs and quality levels affect precision by a lot. Professional-grade keyless chucks can achieve remarkable accuracy with maximum Total Indicator Runout (TIR) of 0.0016 inches or better [3]. Your bit spins with minimal wobble, creating cleaner, more precise holes.

Medium-duty keyless chucks usually have wider runouts of about 0.006 inches [3]. This works fine for general DIY tasks but might not meet professional standards. Keyed chucks, especially those made for machine tools, often provide exceptional concentricity with runout as low as 0.0012 inches [3].

You’ll notice the precision difference most while drilling metals or doing work that needs tight tolerances. Both types work well enough for everyday woodworking and simple home projects if you maintain them properly.

Convenience factors

Keyless chucks shine in ease of use. You can switch bits quickly without extra tools. This saves time on projects that need frequent changes between different bits or driver tips. Just grab the chuck collar and twist to loosen or tighten – no hunting for a missing chuck key [6].

The keyed chuck design means you must keep track of the key, which often gets lost during busy projects. There’s another reason it takes longer – you need to line up the key with the chuck teeth each time you make adjustments [7].

Professionals who switch between drilling and driving tasks streamline their workflow with keyless chucks. Many DIYers love this convenience and find it makes up for the slightly weaker grip in everyday tasks.

Durability considerations

Keyed chucks tend to last longer under heavy use. Their simpler design has fewer moving parts, which helps them serve you longer [6]. Fewer components mean less chance of failure or premature wear.

Keyless chucks pack more complex mechanisms inside. This might make them wear out faster over time. But premium keyless models that use ball bearing designs manage to keep friction low and extend their lifespan [3]. These bearings reduce component wear while improving grip strength.

Some self-tightening keyless chucks might need a wrench to loosen after intense high-torque drilling [5]. This inconvenience actually shows how well the chuck grips during tough jobs.

Your choice between these chuck types depends on how you plan to use it. A quality keyless chuck offers the best mix of convenience and performance for occasional DIY tasks with standard-sized bits. The traditional keyed chuck remains the top choice for industrial applications, heavy-duty drilling, or precision work, even though it’s less convenient to use.

The Inner Workings of a Keyed Chuck Tool

A keyed chuck’s mechanical brilliance shines through its simple design. The keyed chuck uses a special internal mechanism that amplifies force to hold drill bits firmly, unlike its keyless counterparts.

Scroll plate mechanism

The scroll plate sits at the core of a keyed chuck. This spiral-shaped gear creates the foundation for the entire gripping system. The spiral component, also known as the scroll gear, has precisely machined grooves that mesh with the chuck jaws’ teeth [8]. The spiral pattern turns rotational movement into simultaneous radial movement when you rotate it.

The design makes all three jaws move together perfectly. They move toward or away from the center at exactly the same speed. This perfect timing will give a precise drilling operation, and the chuck grips both round and hexagonal pieces within hundredths of a millimeter [9]. Even pressure distribution across all jaws happens because of the scroll plate design, which centers the bit perfectly.

How the key engages with the chuck

The chuck key lets users tighten or loosen the chuck around a drill bit. Each key has a toothed pinion gear that fits into matching teeth on the chuck’s outer edge [10]. These teeth create a gear connection that turns the user’s rotating force into scroll plate movement.

Users insert the key into one of three holes placed around the chuck’s edge to operate it. A clockwise turn of the key tightens the chuck by spinning the scroll plate, which closes all three jaws around the drill bit at once [11]. Turning it counterclockwise loosens the grip so you can remove or change the bit.

Force multiplication principles

Keyed chucks excel at multiplying mechanical force. The gear ratio between the key’s small pinion and the chuck’s larger gear ring takes a small input force and this is a big deal as it means that the output [3]. Users can achieve clamping forces over 75 ft-lbs [3], which is nowhere near what human hands could do with a keyless chuck.

The chuck key’s length acts as a lever that multiplies the applied torque through basic physics. This combined advantage explains why professional users say keyed chucks provide “gorilla grip tightening” [12]. This force multiplication is vital for heavy-duty jobs where the bit must not slip.

The key’s gear system turns regular hand strength into powerful, precise clamping pressure that spreads evenly across all jaws. Keyed chucks remain the top choice for industrial work where maximum grip strength matters most, even as keyless designs become more popular for convenience.

Choosing the Right Chuck Size for Your Needs

Your choice of chuck size makes a huge difference when you buy a power drill. The right size lets you handle more projects and get better results from your tool.

Standard chuck sizes explained

Chuck size tells you the biggest drill bit shank that fits your drill. Manufacturers measure this in inches to show what bits work with your drill. You’ll find three main sizes in stores:

1/4-inch chuck: These compact chucks show up mostly on lighter-duty drill drivers. They give you great control but limit your bit options [13].

3/8-inch chuck: Most household drills come with this size. It hits the sweet spot between versatility and power for typical DIY jobs [13].

1/2-inch chuck: Professional and heavy-duty models usually feature these larger chucks. They handle bigger bits for tough jobs [13].

Matching chuck size to application

The type of work you do most often should guide your choice. A smaller 1/4-inch or 3/8-inch chuck works great for basic tasks like putting furniture together or hanging pictures [2]. Construction work and drilling into tough materials need a 1/2-inch chuck for better stability and more power [2].

Your working material plays a big role too. Harder surfaces like concrete or metal need larger chuck sizes to deliver enough torque and stay stable [13]. Many pros suggest getting a 1/2-inch chuck because it’s better to “have the bigger size and not need it, than need it and not have it” [14].

Impact of chuck size on drill performance

Chuck size links directly to what your drill can do. Bigger chucks usually mean more powerful motors that can push larger bits through tough materials [15]. This might make you think bigger is always better.

Larger chucks add weight to your drill and can make it harder to use in tight spots [2]. This matters a lot when you work overhead or need precise control in small spaces.

Chuck size also determines which special bits and accessories you can use. The right size ensures you won’t get stuck halfway through a project because your bits don’t fit [2].

Advanced Applications for Keyed Chucks

Keyed chucks are a great way to get results in industrial settings of all sizes where precision and reliability cannot be compromised. The strong design handles tasks that would overwhelm consumer-grade tools.

Professional and industrial uses

Manufacturing environments commonly use keyed chucks on stationary drilling machines and lathes. The superior clamping force stops dangerous bit slippage during continuous operation [3]. These industrial-grade chucks apply clamping forces that exceed 75 ft-lbs, making them perfect for production environments [3].

CNC precision keyed chucks showcase the best of manufacturing technology. They feature maximum concentricity with runout as low as 0.0012 inches [3]. This precision allows high-speed CNC equipment to perform milling, drilling, reaming, and tapping operations at exact standards.

Professionals rely on keyed chucks every day. These tools work especially well with hole saws and mixing mortar applications that need maximum torque [1]. Yes, it is true that keyed designs consistently beat keyless alternatives for repeated opening and closing with maximum clamping pressure [1].

Specialized keyed chuck variations

Super ball-bearing keyed chucks use sophisticated bearing systems. This reduces friction in the tightening mechanism and improves grip on drill shafts [16]. Premium models include hardened and ground components built for tough machining conditions [16].

Stainless steel keyed chucks fill specialized roles in food, medical, and dental industries. These environments need corrosion-resistant materials to meet sterilization requirements [3]. The INOX line of chucks delivers sanitary finishes and reliable performance in challenging environments [16].

Plain bearing keyed chucks come with one-piece gear rings and sleeves. This design eliminates tooth breakage risks and suits stationary drilling, turning, milling, and woodworking machines perfectly [16].

When a keyed chuck outperforms alternatives

Keyed chucks shine in applications that need extended operation under extreme conditions. Professional users who rely on their tools to make a living choose keyed models for durability and consistent performance [1].

Jobs that need regular bit changes while maintaining maximum clamping pressure benefit from keyed chucks. They provide reliability that entry-level keyless models simply cannot match [1].

Conclusion

DIY enthusiasts and professionals need to know about chuck mechanisms. Keyless designs are convenient, but keyed chucks excel at heavy-duty work that needs maximum grip strength and precision.

The right chuck size makes a big difference in your drilling results. A 3/8-inch chuck works well for most home projects. Professional users should opt for 1/2-inch models to handle bigger bits and tougher materials. Keyed chucks give you a mechanical edge by generating over 75 ft-lbs of clamping force. This makes them essential for demanding industrial work.

The ICISIVIS Chuck Drill is worth looking into if you’re a professional. It performs well in projects of all sizes. Your specific needs will determine whether you choose a keyed or keyless design – it’s a trade-off between convenience and holding power.

Chuck quality plays a crucial role in drilling accuracy and how long your bits last. If you do precision work, look for models with minimal runout. For tough materials, you’ll want strong clamping mechanisms. Getting the right chuck type and size will improve your drilling performance and help your tools last longer.

FAQs

Q1. What are the main differences between keyed and keyless chucks? Keyed chucks provide stronger gripping power and are more durable, making them ideal for heavy-duty applications. Keyless chucks offer greater convenience with quick bit changes but may have less clamping force. The choice depends on your specific needs and the type of work you’ll be doing.

Q2. How do you properly tighten a keyed chuck? To tighten a keyed chuck, insert the chuck key into one of the holes on the chuck’s periphery. Turn the key clockwise to close the jaws around the drill bit. Apply firm pressure to ensure a secure grip, but avoid over-tightening as it can damage the chuck’s internal components.

Q3. What are the standard chuck sizes, and how do I choose the right one? The most common chuck sizes are 1/4-inch, 3/8-inch, and 1/2-inch. Choose based on your typical projects: 1/4-inch for light-duty tasks, 3/8-inch for general household use, and 1/2-inch for heavy-duty work or when using larger bits. Consider the materials you’ll be drilling and the bit sizes you’ll need.

Q4. Can a keyless chuck be replaced with a keyed chuck? Yes, it’s possible to replace a keyless chuck with a keyed chuck on many drill models. This modification can be useful if you need more clamping force for demanding tasks. However, ensure compatibility with your specific drill model before making the switch.

Q5. What are some advanced applications for keyed chucks? Keyed chucks excel in industrial settings, particularly on stationary drilling machines and lathes. They’re preferred for precision work in manufacturing, CNC operations, and tasks requiring maximum torque, such as using hole saws or mixing mortar. Specialized variations like stainless steel chucks are used in food and medical industries where sterilization is crucial.

References

[1] – https://www.quora.com/What-is-better-a-keyless-or-a-keyed-power-drill

[2] – https://www.zhejiangbried.com/blogs/what-are-some-tips-for-choosing-the-right-chuck-size-for-a-drill

[3] – https://www.mscdirect.com/basicsof/drill-chucks

[4] – https://baer.tools/en/blog/drill-chuck-types-everything-you-need-to-know?srsltid=AfmBOoqEPuoN7A0_29dS4cIT1mzKmqgz3dEzNAVIaBFMStHq2Q0b08gD

[5] – https://woodworking.stackexchange.com/questions/3405/why-are-keyed-drill-chucks-still-available-for-modern-tools

[6] – https://www.zhejiangbried.com/blogs/what-is-the-difference-between-keyless-chuck-and-keyed-chuck

[7] – https://ridiculousmachinetools.com/blog/the-evolution-of-drill-chucks-from-manual-to-keyless/?srsltid=AfmBOoqYa5s9rNgoGEKT6kW9A5FlxfSesCcVSB5tqSU0iIQ3fMPLV9du

[8] – https://www.cutwel.co.uk/blog/expert-guide-on-scroll-chucks.html?srsltid=AfmBOorosG6hXAt0ydehMA6WWV3SCNmsxH3BdtvhCeAqscqweE3JI0SD

[9] – https://openoregon.pressbooks.pub/manufacturingprocesses45/chapter/unit-3-chucks/

[10] – https://www.quora.com/What-does-a-drill-press-chuck-key-do

[11] – https://www.workprotool.com/news/how-does-the-drill-chuck-function-58966594.html

[12] – https://www.quora.com/Do-keyless-drill-chucks-provide-as-much-clamping-force-as-a-Jacobs-chuck

[13] – https://www.lowes.com/n/buying-guide/power-drill-buying-guide

[14] – https://forum.toolsinaction.com/topic/13624-confused-on-chuck-sizes/

[15] – https://ronixtools.com/en/blog/how-does-a-drill-chuck-work/

[16] – https://llambrichusa.com/keyed-chucks/

How a Drill Chuck Works

The core function of any drill chuck is to secure the drill bit firmly while the drill rotates. To tighten the chuck, insert a drill bit and rotate the sleeve (or use the chuck key). This grips the bit. This process keeps the drill bit from slipping. It ensures stable, accurate, and efficient drilling.

In a keyed chuck, the chuck key goes into a small hole on the chuck. It engages teeth that let you tighten or loosen the jaws. This gives a strong grip, especially with tough materials or large drill bits.

Keyed Chucks: The primary function of the keyed chuck is to provide maximum grip strength. Using a separate chuck key to tighten it lets you apply more force. This ensures the chuck securely holds the drill bit during high-torque operations. This is vital when drilling into hard materials, like concrete or steel.

In a keyless chuck, the jaws can be tightened or loosened by simply turning the chuck by hand. It is fast and convenient. But, it may not grip as well as a keyed chuck for heavy-duty tasks.

Keyless Chucks: Keyless chucks are great for quick, easy use. They’re best for jobs that require frequent bit changes. Their convenience comes from the fact that you don’t need any extra tools. You can quickly adjust the chuck by hand. This is a great benefit for small tasks or when you need to switch between different-sized drill bits.

Hybrid Chucks: Hybrid chucks are designed for users who need both speed and security. These offer some benefits of keyless chucks. They add the stability of a keyed chuck. So, they are ideal for those who do varied tasks all day.

The Relationship Between Torque and Chuck Performance

Chuck size and torque are key to peak performance. Selecting the right combination ensures efficiency and prevents unnecessary strain on your tools.

For lighter torque levels, from 300 to 500NM, use a 1/4-inch or 3/8-inch chuck. It has the right grip and control. These sizes are best for precise tasks. They include assembling furniture, fastening small parts, and delicate auto repairs. The compact design of smaller chucks complements lighter torque levels without sacrificing efficiency.

When dealing with moderate torque, from 600 to 1000NM, a 1/2-inch chuck is a practical choice. It can handle tasks from tightening bolts to mid-level construction. The larger diameter lets it handle greater forces. This ensures stability and durability during operation.

For heavy-duty tasks, with torque over 1200NM and up to 2000NM, larger chucks are essential. Use 3/4-inch or 1-inch chucks. These sizes are designed to withstand significant forces without slipping or deforming. They provide the grip needed for industrial-grade tasks. These include securing bolts in heavy machinery and assembling structural components.

A proper match between chuck size and torque prevents inefficiency and wear. If the chuck is too small for the torque, slippage or damage can occur. A large chuck with low torque may cause overcompensation and wasted effort.

Considering this relationship ensures your tools perform reliably and extends their lifespan. For tasks from light assembly to industrial work, align torque with chuck size. This ensures precision and effectiveness.

Reading your work felt like discovering a new language — one that speaks directly to the heart while still offering intellectual depth.